For many years I have had a flat screen TV with built in DVD player on my workbench. I inherited it so don't know much about its past. I have never used it let alone even tested it to see if it switches on preferring the less distracting radio or CDs or even showing my age, my collection of cassettes! However, having a collection of railway and model making DVDs which I never get the chance to watch as Mrs. Woody is watching the latest murder mystery TV show on the main WMD TV or I am in the Man Cave listening to the radio/music I thought I would just see if this flat screen TV works - and it dose so I have gone Hi-tech! So I have been watching some Steaming Around Britain DVDs which is great as I have never seen them before and surprisingly not that distracting as I tend to just glance up to see what sounds the interesting parts - just like communicating with Mrs. W - I really hope she doesn't read that bit!

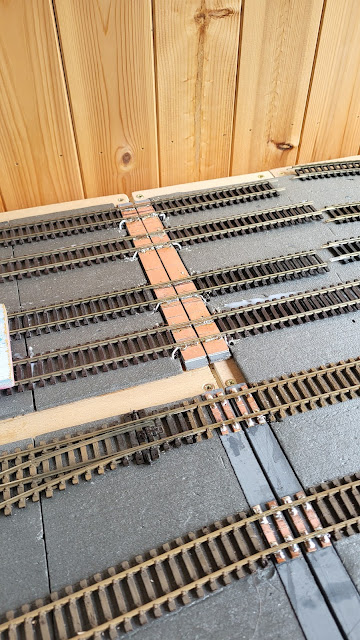

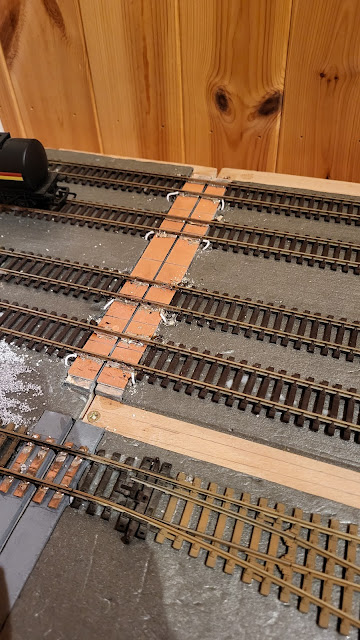

The proof in not being distracted is that I finished the other end of the platform base. As you can see this coincided with a splendid bit of film of a steam train heading for Mallaig in Scotland!