It rained last night disturbing my slumber but reminding me that after nearly a month the resin water on the narrow gauge layout should really have dried out by now. So in the light of day I had another look today and pulled back the cover that I put over the water to stop dust getting onto the surface. Whilst apart from a small patch that is still sticky the rest has hardened off. That should be joyful but having pulled the cover off this was the first time I had seen the complete river since pouring the resin. It was slightly disappointing! Whilst a small amount had leaked at the edge of the baseboard the rest had shrunk! It was lower than when I poured it. I can only assume that as it dries it shrinks. As I had sealed the river bed with several coats of varnish before pouring the resin I can not see it having been absorbed by the landscaping.

Well I could leave it as it is as a token gesture to a dry summer or I do have two thirds of a bottle of the resin left so I can increase water levels which is what I will do. However in the hope of a warm summer I will await pouring anymore resin until later in the year when the hopefully warm weather will lead to a setting time of days rather than weeks!

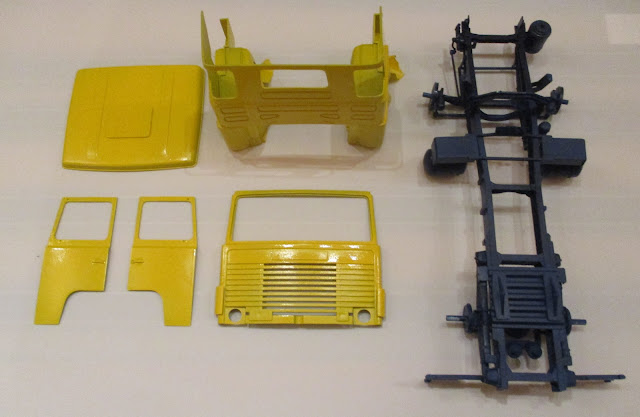

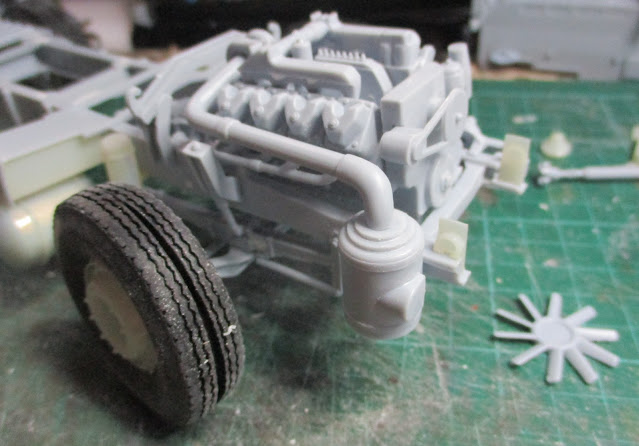

Following a bike ride (360 miles this year so far) I went back to spend an hour on the Scania 143H. The steering box and linkages have been built and installed and one or two more bits added to the chassis or prepared for fitting such as the various air tanks and fuel tank. The engine needs a bit more work as well but it is coming together.