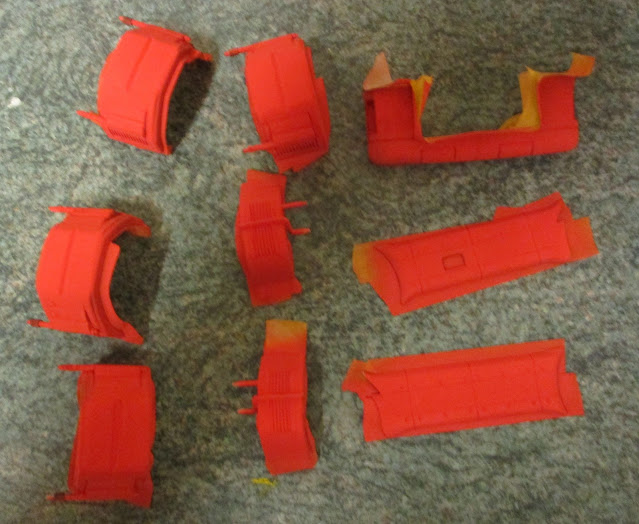

Even the best laid plans sometimes go differently to expected and that is what happened today. I will go into the reasons another time but I did manage to get some undercoat on the mudguards, front valance and side skirts of the Scania 143 or as I have termed it, simply red!

Recording my progress, or usually the lack of it, in building kits, creating model railways and other related and sometimes unrelated matters!

Search this blog

Sunday, February 13, 2022

Saturday, February 12, 2022

Sound advice!

A somewhat windy day when I felt as though I was riding into a brick wall on this mornings bike ride. However the journey home was a breeze with the wind behind me. Something that has stuck with me since I started serious bike racing in my teens was a piece of simple but very sound advice from another experienced rider which was that if you can cycle into the wind on your journey out do that so the wind blows you home. Nothing worse then turning back and having to fight the wind on your way home. Strange how advice like that sticks with you for your life and something I pass onto others.

Other sound advice I have found during my years of model making is that there are times when you need to take your time and think about what and how you are going to do something before you actually do it. It may sound logical but sometimes, just like chess you need to be thinking several moves ahead. Not something I did in my earlier years when I built a model and then wondered how on earth I was going to paint it so that it didn't look like something involved in a paint factory explosion. Take the rear wheels on the Scania 143H. I have not fully assembled them so that it is easier to paint the hubs which are a different colour to the rest of the wheel. I also did this sometime ago well ahead of painting the other wheels so that they were all ready to be painted in one go.

Today I actually started the painting process not only for the wheels but also the mudguards, front valance and side skirts. The rear of the valance and skirts in real life are undersealed to resist stone chips and rust. Therefore they would not look right being painted in red which will be the colour on the front and upper faces of the various items. So using that sound advice of thinking ahead I painted the appropriate surfaces with black paint. I don't want the surfaces which are to be red undercoated in black as this will make the red too dark as the undercoat affects the final look of the final top coat of paint. Having matt varnished the black surfaces the parts were left to dry.

As I also need the wheels to be painted ready for fitting before I fit the mudguards these were painted black too. The wheels will eventually be aluminum in colour and black is the perfect undercoat for that paint. The four wheels with the red hubs had to be masked before painting. I actually made one mask by rolling some paper to the diameter of the hub, taping it and then using it as I painted each wheel separately. I can then use the mask again when I airbrush the aluminum paint.

As you can see painting can be a dirty process but on occasions can get you out of assisting Mrs. W with folding the washing! As it is acrylic paint it scrubs straight off under the tap once the washing folding activity has been completed!

Hoping that tomorrow will allow the various parts to be painted in their final top coats so the areas painted black need to be masked off. This is also where thinking ahead plays dividends. It will be much easier to touch in the black areas, which are mainly hidden from sight, with a brush should any red paint seep under the masking. Touching up the highly visible red paint with a brush would be a much more difficult thing to do - for me anyway! An hour of masking will hopefully ensure a neat job. All will be reveled soon!

Friday, February 11, 2022

Further tales of plastic butchery!

Thursday, February 10, 2022

Light bulb moment!

A great sunny day which saw me clock up 512 miles on my bike this year so far. Even Smudge the cat came out of her basket curious at the brightness outside and took in some of the sun before heading back in for something to eat and another sleep. She has a hard life!

It was also sunny in the Man Cave AKA The Room of Gloom as the Heller Scania 141 LB made progress.

First thing was to glue the two part tyres together. As these are rubber plastic cement was not going to work and my trials with super glue failed miserably. Pondering this as I fixed a puncture on my bike I suddenly had that light bulb moment. The adhesive used to adhere the repair patch to the inner tube glues rubber to rubber! Yes it did work on the model tyres as well! Half an hour with my puncture repair kit on the workbench had the tires glued. I also remembered to return my repair kit to the bike or that could be a swear jar moment when a future puncture occurs.

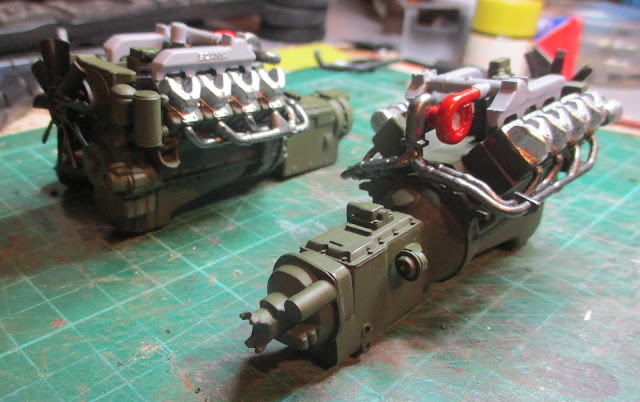

The engine has now been glued in and the wheels attached to the axles and just await their center caps to be fitted. The cab front has also had various decals applied and the model now looks like this.

Not many parts to fit now but the further into the build you get the more fearful you become of something going wrong! Hopefully nothing does.

Wednesday, February 9, 2022

Sometimes you have to be destructive to be constructive!

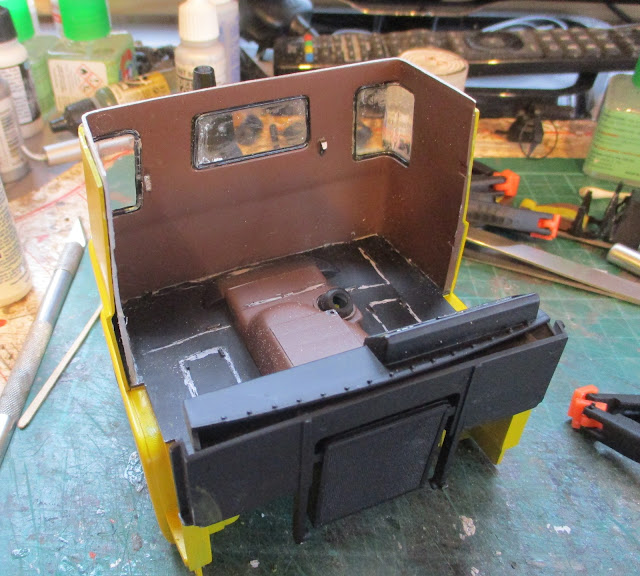

As I highlighted yesterday I needed to take drastic action to try to make the inner cab unit fit the outer cab shell on the Scania 141LB. First try was a lot of clamps and leaving the model on top of a radiator for a while. As the radiator is a central heating water filled one there was no risk of fire but always a risk of damage to the paint. The idea was that as the plastic heated up and became a little more flexible the clamps would pull it into place. That was the theory and the model was completely successful in proving me wrong! Rather than breaking into a Basil Fawlty moment and threatening the model I sat back and thought that there was no other way remaining other than to be destructive so I could deal with the inner cab unit. I therefore had to be destructive! Out came all the cab innards and it was not easy as my glue joints were for some unusual reason strong! Seats, bunks and steering wheel all ended up on the work bench. It looked terrible!

I felt a bit like Edd from Wheeler Dealers with a stripped out cab putting right the underlying problems. I had to shave parts off the lower back joint of the inner cab part and file parts off where it matches up with the passenger door. I also had to cut chunk out there and cut back and reshape and rejoin the part. The result was that the panel fitted apart from a gap at the side which cannot be seen. With that issue resolved it was back to putting the parts back in with the advantage that there was no annoying Mike Brewer telling me he had worked hard in having the glove box emptied! Anyway I am back to this and yes I have tested that the roof fits!

With all the handling that the cab has had there are some marks on the paintwork which I am hopeful will polish out just like on Wheeler Dealers!

Tuesday, February 8, 2022

Pulling levers and turning wheels!

Another day at the Rocks by Rail Museum. Although there were only four of us there we got a bit more ballasting and track leveling done. With a minimal crew on hand I was allowed to pull a point lever which was a first for me and operate the chutes on the ballast wagon by turning the operating wheels which again was a first. I think I didn't make too much of a mess of it as the loco traversed the point OK and the ballast came out of the wagon in the right places!

There is always some ballast that refuses to come out so in this case Richard went in to poke it out.

Looking at where we are now with the ongoing track ballsting and leveling shows just how far we have progressed. We started near to the engine shed in the far distance of this photo back in October.

Walking down the track today I noticed that some of the concrete sleepers have the old WD or War Department mark on them.

These apparently date from the First World War. Not bad for being over 100 years old!

On the Scania 141LB build my fears about dealing with warped and twisted parts and these causing problems have proved correct! No amount of pulling levers or turning wheels or even pushing and coercing the parts makes this problem go away!

I can see I will need to take some drastic action and get another larger swear jar!

Monday, February 7, 2022

Nerve wracking times!

The time has come with the build of the Heller Scania 141LB to put the cab exterior around the cab interior. It is nerve racking as I am dealing with painted parts, glazing and with a kit that has twisted and warped parts that have no doubt caused some issues with the subassemblies which probably show up in yesterdays pictures. This particular part of construction could well see the need for a much larger swear jar!

First job was to fit the glazing into the rear windows using Deluxe Materials Glue and Glaze which works well.

Once the glue is set I can then go onto the difficult part so there will be much trial fitting and no doubt shaving of parts to get it to all fit.

I did have the opportunity to spray up the front bumper in white which can await fitting whilst I fill the swear jar!

Sunday, February 6, 2022

Getting there!

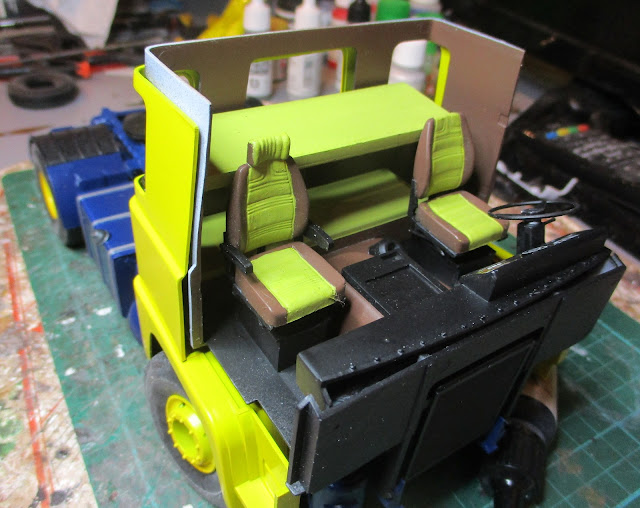

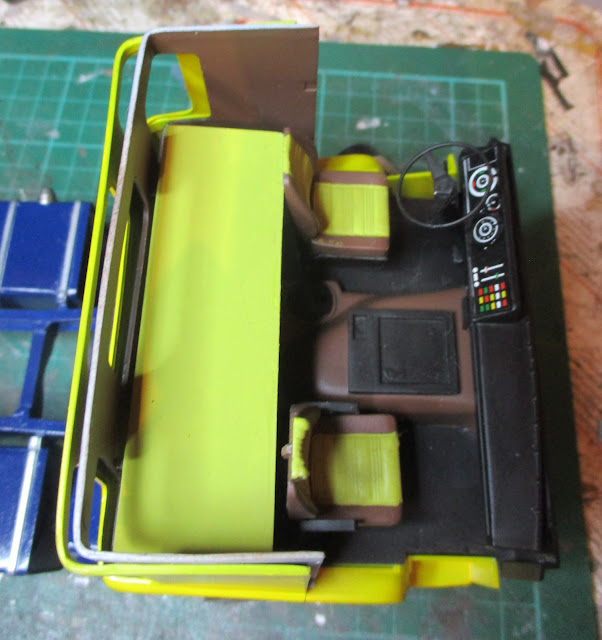

Getting there, is the usually response from me to Mrs. Woody's enquiries as to progress on her list of jobs. Getting there, is usually that unspoken code for, well its not really progressed much but I am working on it - honest! However with a day of doing various different jobs today and getting there with some of them, I did manage to fit in some model making between and in this case the model Scania 141LB is indeed actually getting there but don't tell Mrs. W! Some airbrushing, some gluing and some balancing of parts towards the end of the day to see what it will look like. The wheels still need attaching properly, the exterior of the cab is held up by a paint bottle but the interior is more or less finished as is the engine and the mud guards are now attached after another coat of black paint on the rubber parts. So here we are - getting there! Now where is that list of jobs......

Saturday, February 5, 2022

Fuel for thought

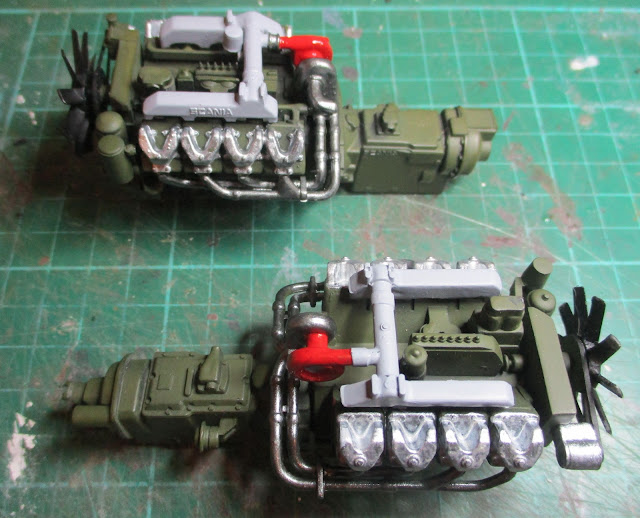

This evening I managed a couple of hours of work on the Scania 141LB. Thoughtfully, having painted the straps on the fuel tanks yesterday I was able to mount them to the chassis which gave that a bit more of a look of a complete chassis. I also have matt varnished the engine block as well as the one for the Scania 143 and applied a wash to highlight detail on both. The mudguards for the 141LB have also been painted, unusually for me, using a conventional brush. As it was a black matt paint used to represent rubber parts it should be OK. Putting it all together (the mudguards are yet to be properly attached) it actually is looking good to my aging eyes! The coloured engine certainly adds something.

I did grab a few minutes earlier toady to put a first coat of red onto the Scania 143 rear wheel hubs which I primed in white earlier last week. Red can sometimes be an awkward colour to paint as the pigment is not that strong meaning if you apply it with an airbrush it can look very washed out hence an initial coat of matt which has a denser pigment content then the gloss red which I will apply later. Actually sounds as though I know what I am talking about. Now that is fuel for thought! Wonder what Mrs. W thinks?

Friday, February 4, 2022

Masking it!

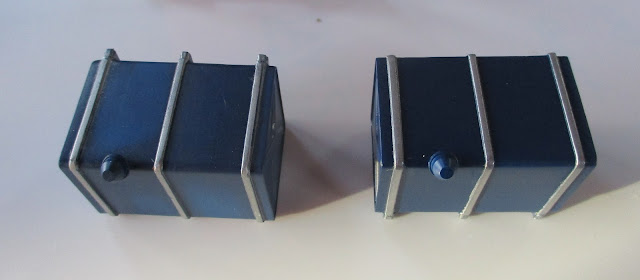

No not masking me up although some would say it might improve my looks! In this case I needed to paint the straps on the fuel tanks for the Scania 141LB in an aluminum shade of paint. I could have tried doing it freehand with a paintbrush but previous experience starting from my early days of childhood has shown me my inability to keep in the lines not only of colouring books but on models as well. So I needed to mask the tanks and then airbrush the silver paint. It took me almost an hour to mask the tanks up but it was worth it. Whilst the paint was in the airbrush I also painted the tank for the Scania 143.

Also taking time but not needing masking were various components on the engine so they look a bit more interesting now.

They need to dry fully and a coat of varnish will be applied before they both get a wash of black to highlight the details. This may sound a bit strange as black hides things but in this case the wash is a very dilute mix of paint that settles in the recesses and around the edges of the models which in effect highlights them.

Putting my efforts together for the day there is not all that much to show but this is sometimes how model making goes - progress is masked by the detail!