Fine tuning might be taken that I have some form of musical instrument that I have spent some time tuning to optimum musical performance. Well there is a drum kit or two or WMD HQ much to the concern of Mrs. Woody. One is an acoustic kit that never sees the light of day these days due to noise considerations and whilst the other is a neighbour and wife friendly electric kit that only I can hear through headphones when I play it, neither has ever had me fine tune them. Instead the fine tuning I am currently involved in is related to my last great project 00 gauge layout.

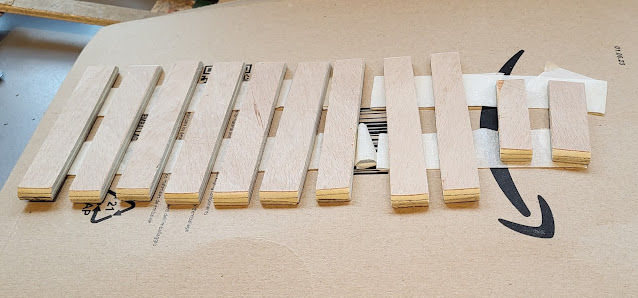

As outlined back on Monday I am currently working on track joints at the baseboard joints and I had cut some plywood pieces that would be located at the baseboard joins to which copper clad sleepers would be attached to which the rail would be soldered. Well the plywood has been cut and painted. Giving it a coat of grey paint seals it against any moisture from the glue when I eventually ballast the track and will also ensure any parts not fully covered by ballast will not stand out as they would if I left the plywood in its natural state.

Luckily Mrs. W had a recent Amazon delivery (not an unusual situation!) and I diverted the discarded packaging from the recycling bin in order to attach the plywood ready for painting.

It certainly made painting easier.

Now back to the fine tuning. To get the best from a model railway the track needs to be level and well laid. Whilst I have a general layout of track, non of it is fine tuned and it shows at some of the joints and the general alignment. Trains run but there are occasional issues which I want to avoid once the track is secured and ballasted. Using Set Track pieces to build a layout at least means that with the set sized pieces and the geometry used it should fit together reasonably well. Mix Set Track and flexitrack and you really have a bit of a nightmare in getting it all to fit properly. Now with my skills, or lack of them, getting track to fit is a challenge! However that fine tuning has to be so I have started.

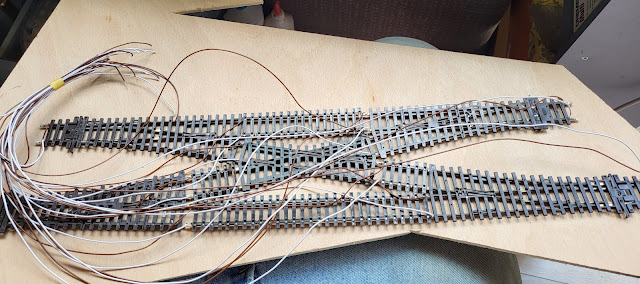

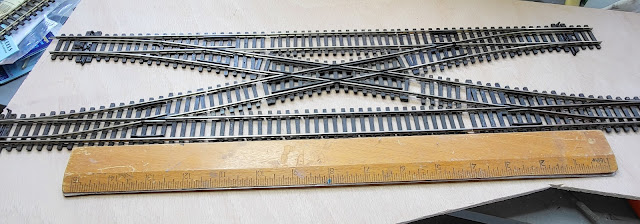

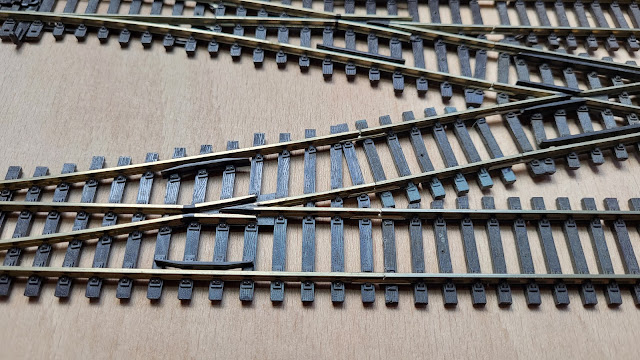

First off is this crossing with four points and a diamond crossing. I have, for ease of doing things, taken it off the layout. Looks reasonable from a distance.

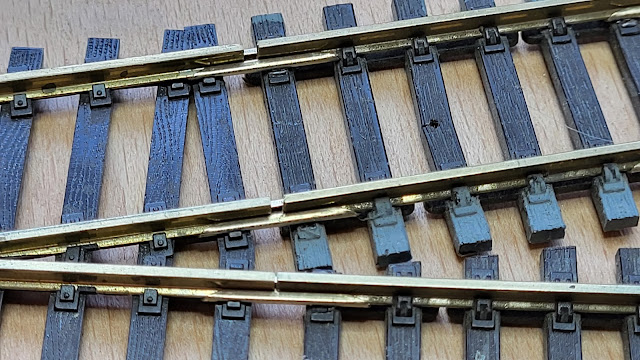

However, take a closer look at this joint. Whilst it is always useful to have some room for expansion that gap is just to big to give reliable and smooth running.

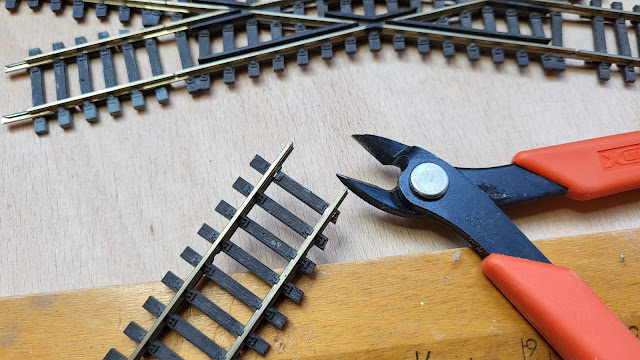

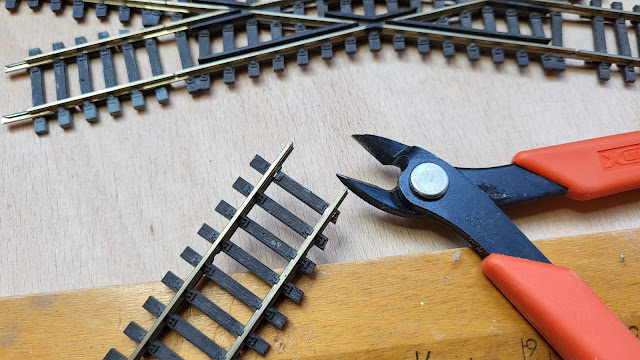

Taking a close look, I determined I needed to shorten the lower piece of track to close the gap so out came the rail cutters.

Having done that the situation was much improved.

The best way to check how straight the track is is to look down its length at a low level. Looks good to me.

Next job is to solder some power feed wires to the underside. Now that will be an interesting job. For this crossing there will be 24 wires! That should test my soldering skills and possibly fine tune my skills at adding to the swear jar!