The other day I had a session just playing trains on my Last Great Project Layout. That involved watching the trains run around the layout - very therapeutic and relaxing! I also had a play with my USA switching layout. This layout is very much about shunting wagons about. The importance of couplers between the wagons and locomotive is always a matter that raises lots of chat and debate between railway modelers. UK outline stock is usually offered with a variant of a coupler which goes back to the 1950s or possibly earlier. It is termed as the tension lock coupler and to put it mildly it is ugly and out of scale. It couples reliably but uncoupling is another issue. There are uncoupling ramps available and some electrical ramp systems but they all have issues. The photo below shows a really nicely detailed class 33 locomotive but with that tension lock coupling on the front it looks somewhat strange and not what you see on the real thing. As modelers, most of us just accept it and I guess we turn a mental blind eye to it.

Meanwhile our American modeling friends have enjoyed the delights of a coupler that actually looks like a real life coupler. It couples reliably and equally it uncouples reliably with the use of a magnet which can either be installed out of sight under the track or incorporated as a crossing point. This photo of one of my USA locomotives shows how much more realistic it looks with what is known as a Kadee coupler.

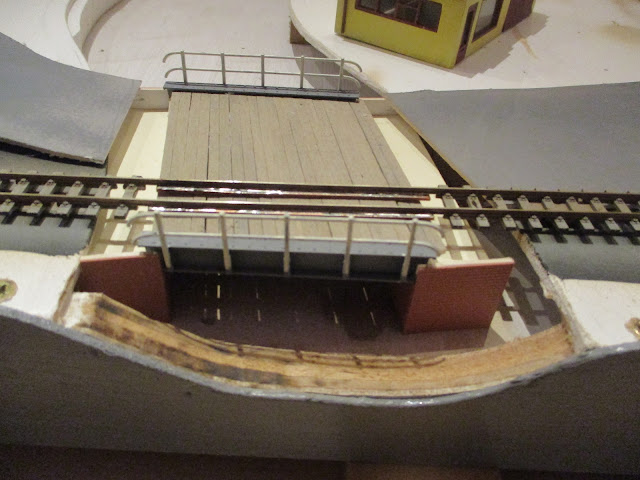

The Kadee coupler has a metal pin hanging under it that is repelled by a magnet - that is it moves away from the magnet. The two photos below show the pin being repelled on the loco as it crosses the magnet which is part of the level crossing on my layout.

If you can imagine the same action happening on an attached wagon's coupling which will move in the opposite direction then you can see in the photos below how the locomotive and wagon uncouple.

The further beauty of the Kadee coupler is that once uncoupled you can push the wagon to where you want to park it on the layout - wonderful!

Why don't UK suppliers put this coupling on UK models? Well there are all sorts of answers but I guess we have just had the tension lock coupling for so long that it is unlikely, because of compatibility between existing and new models, that modelers would take to a new coupling with all the costs of converting old models to couple up with new models. Meanwhile I will enjoy the coupling up delights of the Kadee on my USA Switching layout.