Given the problems I usually come across building models and at present the point motor installation on my 00 gauge layout I was set wondering if I should take up crochet making as I wondered down this road.

I have been here before back in May when these bollards had crochet coronation themed tops and there was a blog post about it available here.. Today there were just various different items but all looked good and what could go wrong if I took up crocheting?

Well all sorts of unexpected problems would probably inflict my attempts at this creative art and as I have no bollards to cover the whole thing could be pointless anyway! So back to my point problems!

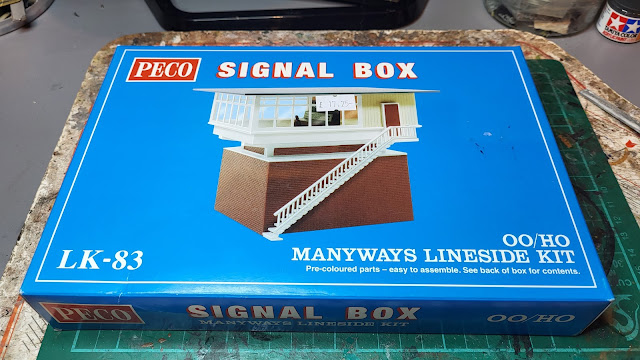

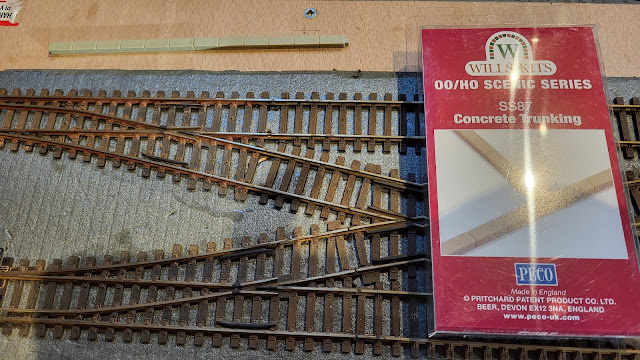

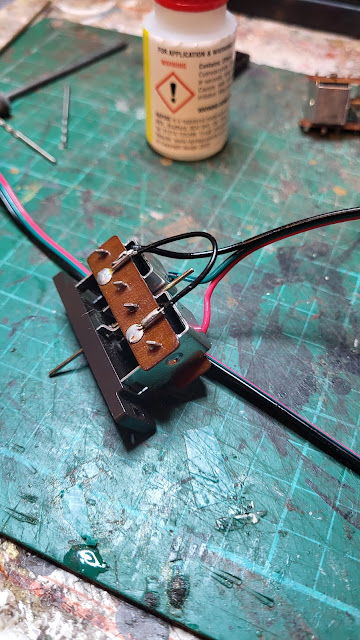

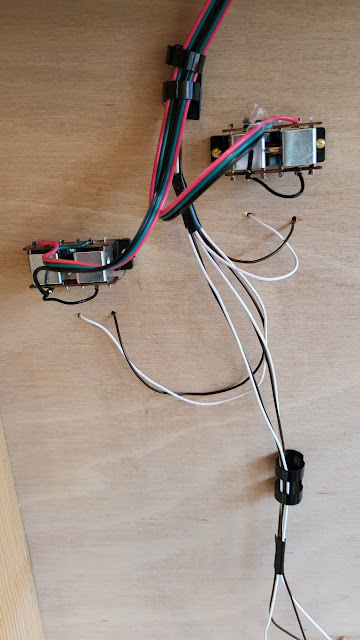

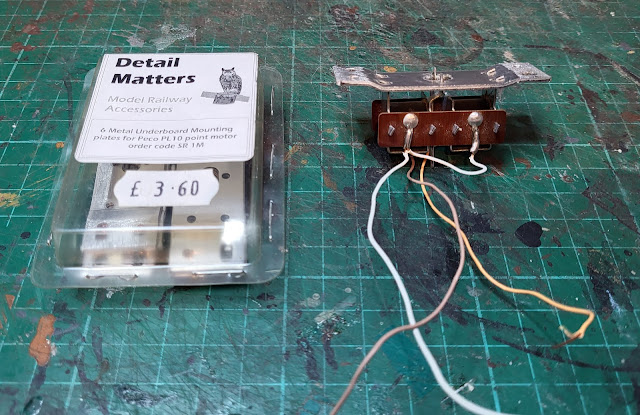

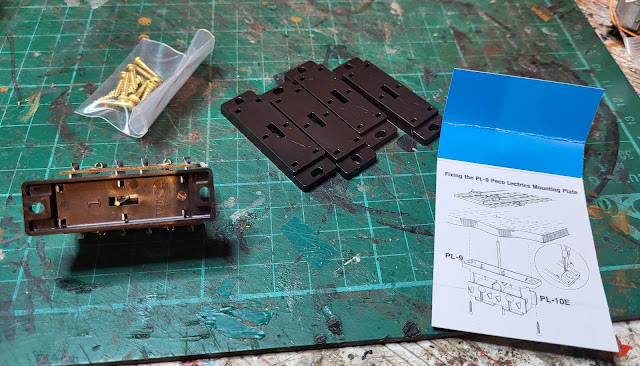

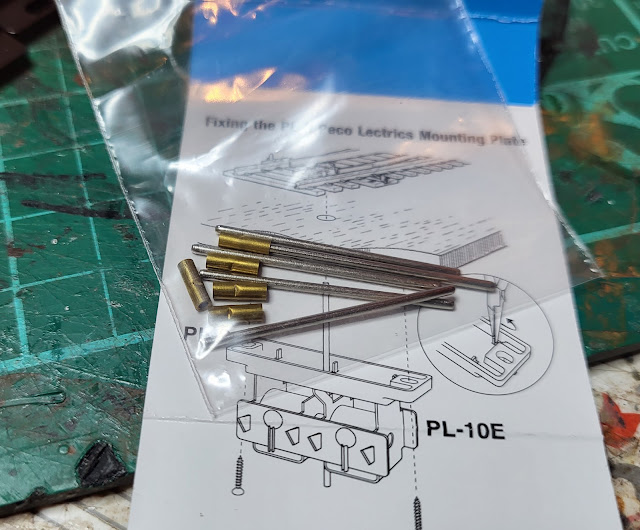

Yesterday I outlined that the point motor actuation pin required an extension and I had bought some ready made but expensive extension pins to make life easy! Wrong! The brass collar to join the point motor pin to the extension pin was too small to fit over the PECO pin! I tried heating it to expand it, drilling it out but no! However not to be put off I went into the depths of WMD HQ stores to find the brass tube I had used years ago to make my own extension pin collars. Ten minutes later I found it which was something I expected to take days to achieve! Anyway, with it found I cut suitable lengths off and used the bought in extension pins and some superglue to fit all the parts together.

Next problem was that the slot through which the pin goes in the PECO mounting plate was too narrow to allow the brass collar through. Out came a file and the slot was widened to allow the collar to go through without touching. With that sorted the point motor was mounted to the plate and the tags on the motor body bent over to secure it to the plate.

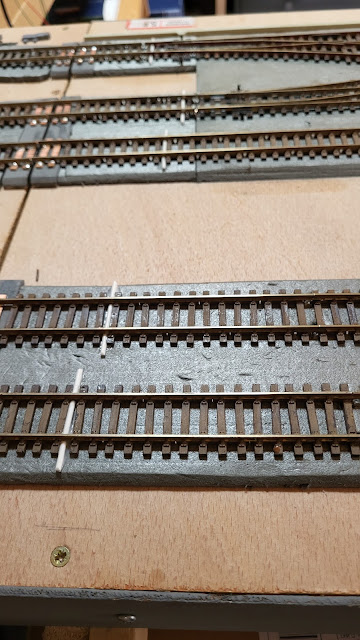

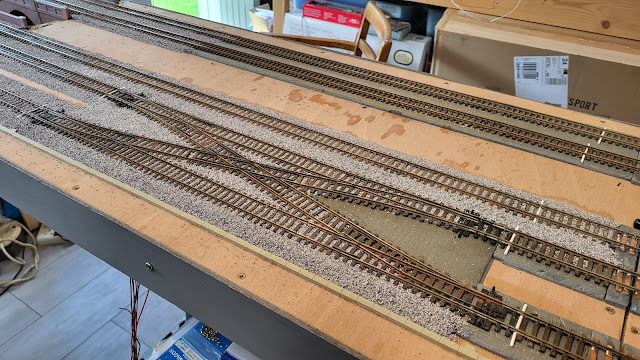

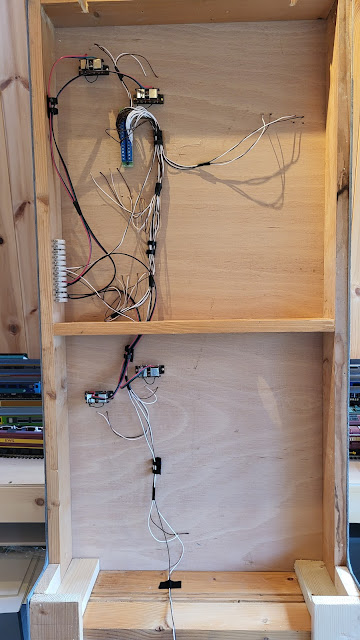

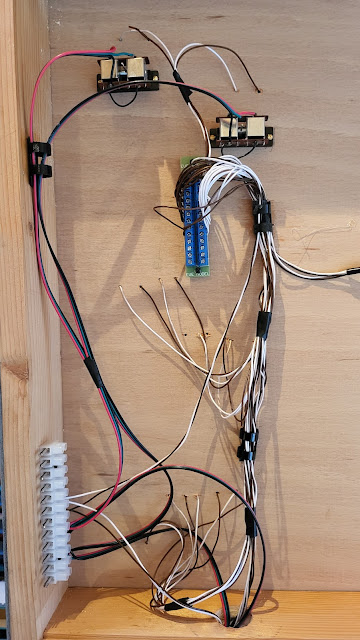

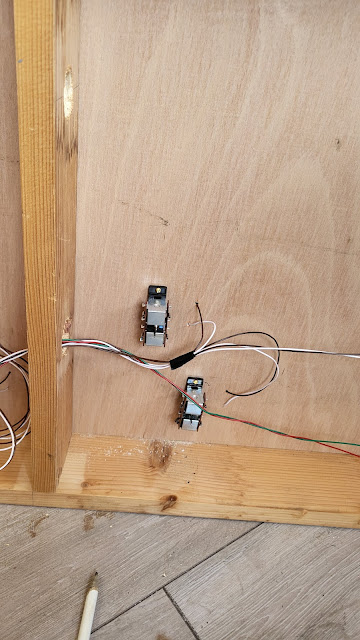

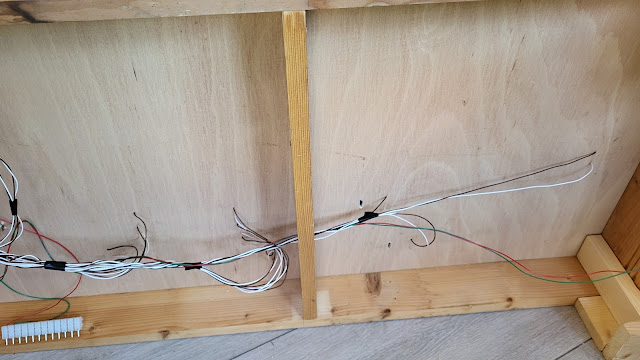

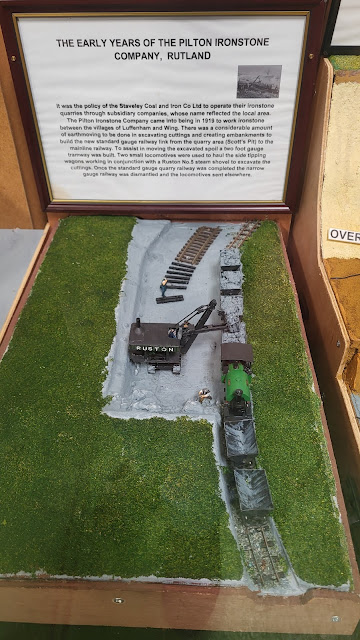

With that done I could begin mounting the motors to the underside of the baseboard. First job is to get the pin through the appropriate hole in the point operating arm - not the easiest job to do when you can only see one side of the board. Once done and the point motor maneuvered so that the point switched smoothly holes were drilled and the plate fastened to the baseboard.

I had to do some work with the track wiring to allow the point motor to be fitted. Basically with the wiring connector mounted to the baseboard edge there was insufficient flex in some of the wiring to clear the point motor. In the end I had to move the connector and it will be mounted to the baseboard as in the photo below.

I am sure crocheting does not have problems like the above but giving it more thought I should stick to what I know and I like model making!