A day with a variety of things I like today. First off a bike ride which woke me up and then off to the Southwell Railway Society's first meeting since February 2020. Never been to the Society before but thought I would turn up following an invite and I had a really good time. There was a presentation from one of the members of old photographs of the railway system around the Whitby and Scarborough area. I know that area from numerous holidays so it was very interesting. I have paid my subs to join for a year but as Mrs. W tells me I should have waited in paying as I only go to places twice and the second time is to apologise!

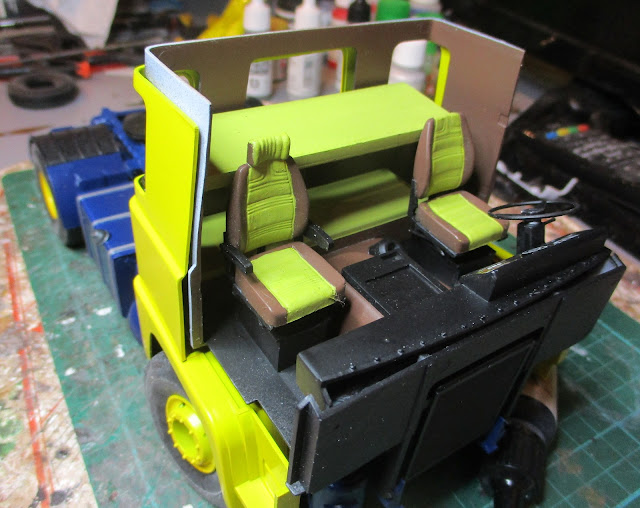

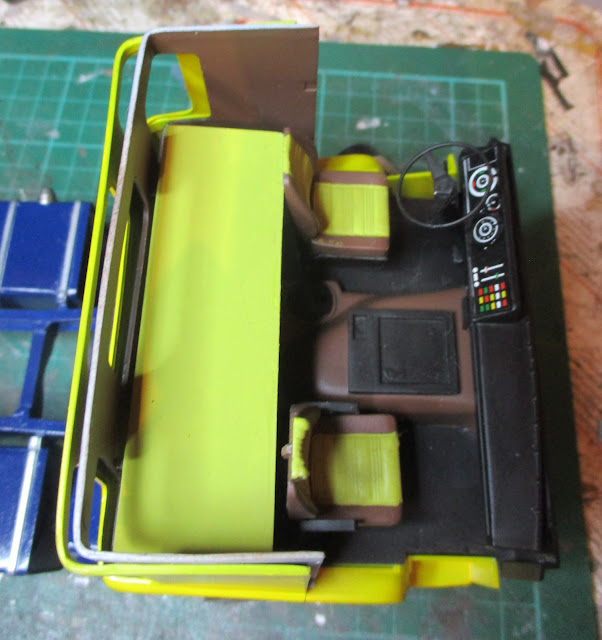

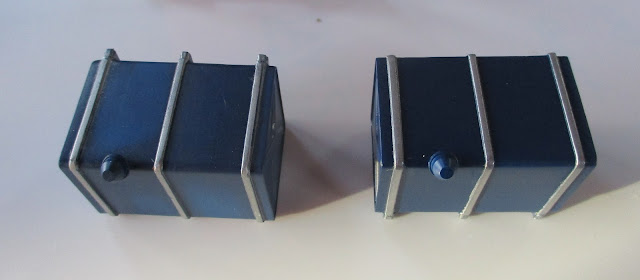

Following a lunchtime catch up with a good friend it was back to WMD HQ where I had a chance to add a few more bits to the Scania 143H chassis. It still looks much the same as it did yesterday so no photo but here are some previous builds.

First off is the Italeri 1/24th scale DAF 95 truck built out of the box apart from a CB antenna back during Christmas 2000. I recall having problems spraying the cab as it was so cold - now that rings a bell with the build of the Heller Scania!. It is coupled up to a Italeri tipper trailer built back in 2010. I literally built the kit in a day but it took a week to paint it. Must have been my fastest build ever!

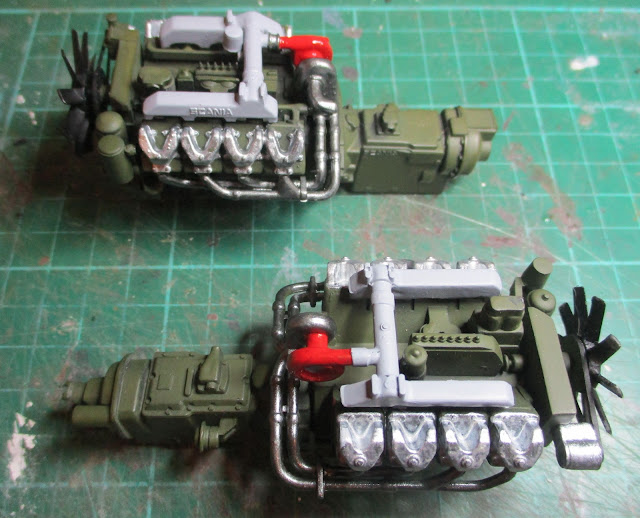

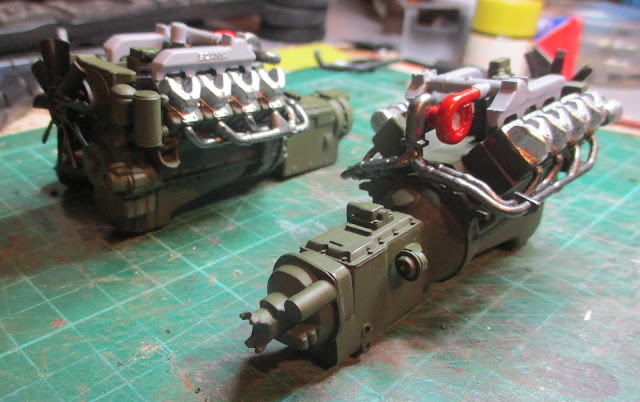

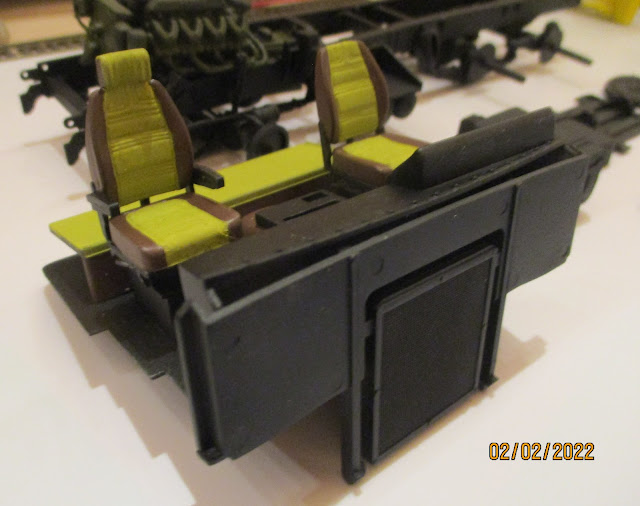

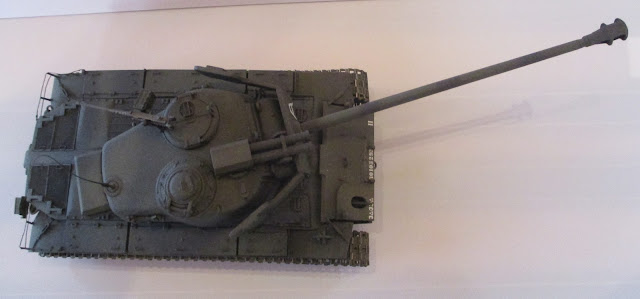

The second kit dates from about 2013 and is the 1/35th scale Hobby Boos kit of the Super Pershing T26E4 Tank. Developed by the Americans in response to the Tiger Tank that out gunned and out armoured most Allied tanks, the Super Pershing had a 90mm gun which on testing put a shell straight through a Jagpanzer IV and it embedded itself in the ground behind. The barrel of the gun was a bout twice the length of most other tank guns at the time. Unfortunately it only entered into service in January 1945 and only 20 saw active combat until the war ended later that year.

To complete this day of variety will be a BLT for dinner but no spices, just mayo!