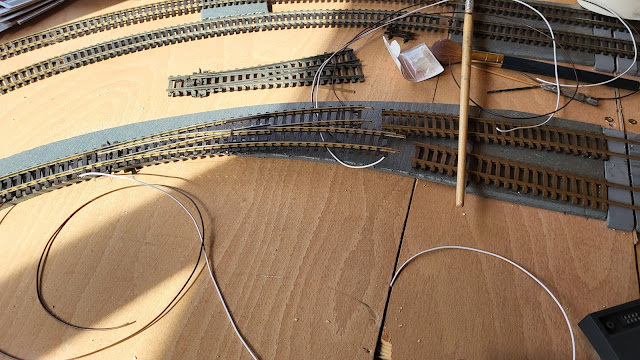

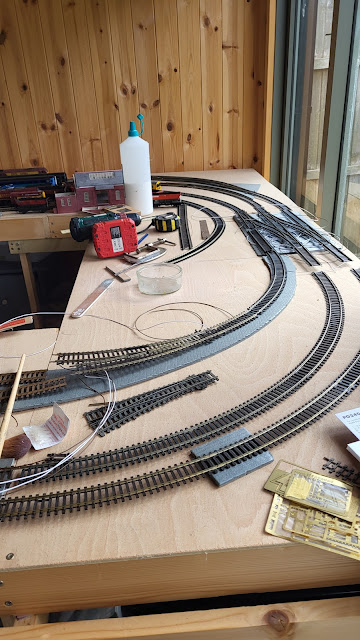

Sometimes a day comes along when you think that you can get a job done in a couple of hours and it ends up taking 5! Well today was one of those days. I set out to wire up the point complex on the other side of the layout and had visions of having the job done as well as several others. The drilling of various holes through the baseboard for wires and point motors went smoothly enough. Then the frustrations started. The points in this complex are Hornby. Not my first choice but as I had them they were used as part of this layout and the cost of replacing the eight of them (four in the complex that I did last week and four in the complex I dealt with today) would be over £100. One of the problems with Hornby track is that the metal or the covering on the metal that they use for the rails will not accept solder very well. Occasionally a good joint will be formed first time but the majority of the time I have to scrape the metal to try to get a decent surface for the solder to adhere to. I do get some joints that look OK but if I give them a tug they come away so I have to start again. Very frustrating! However I have managed it! The curved Peco point took just five minutes to do!

No comments:

Post a Comment